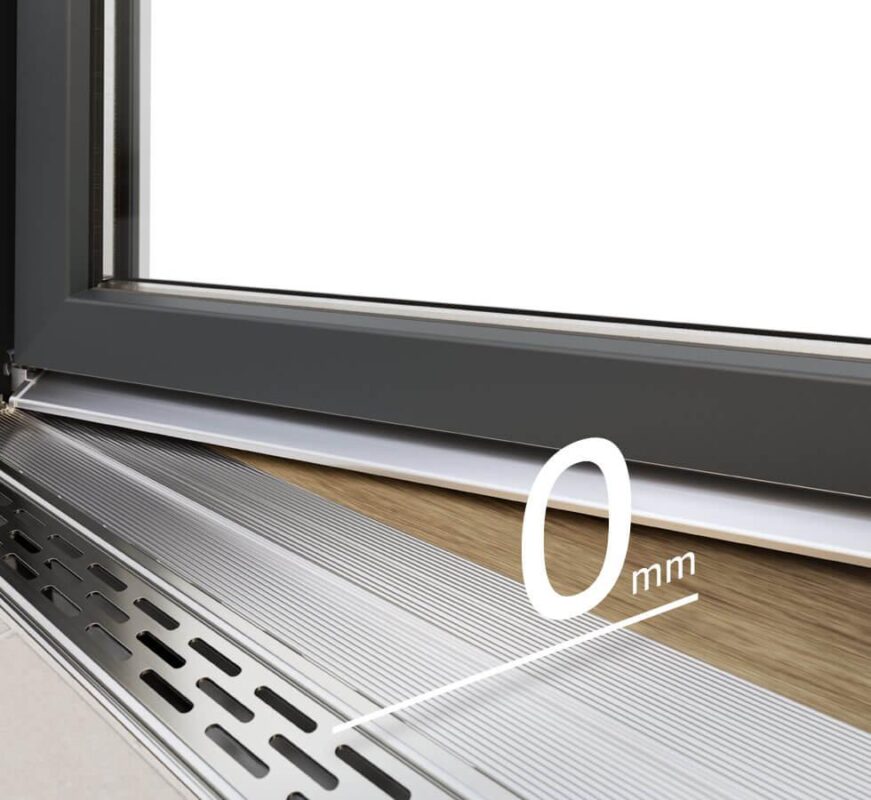

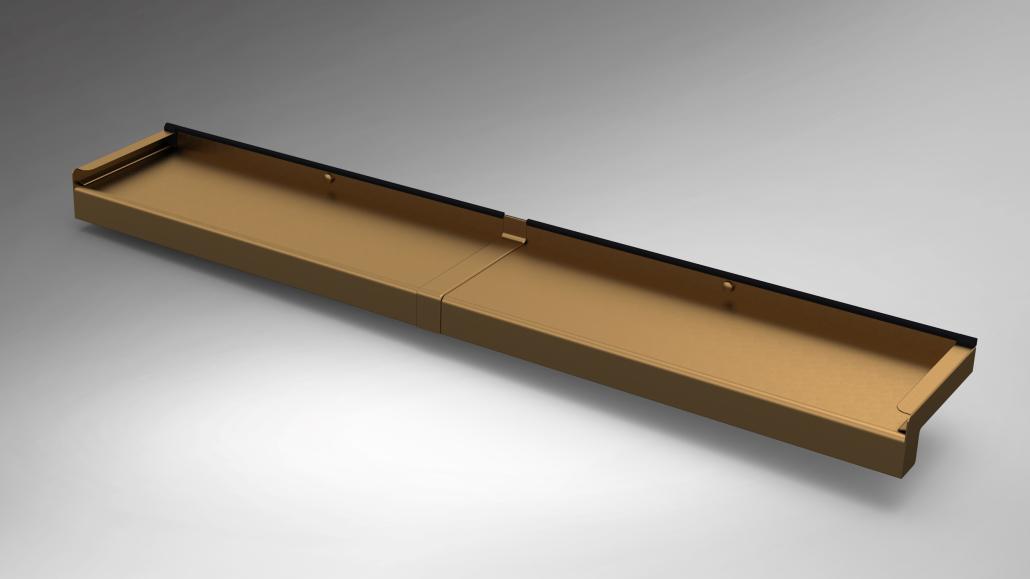

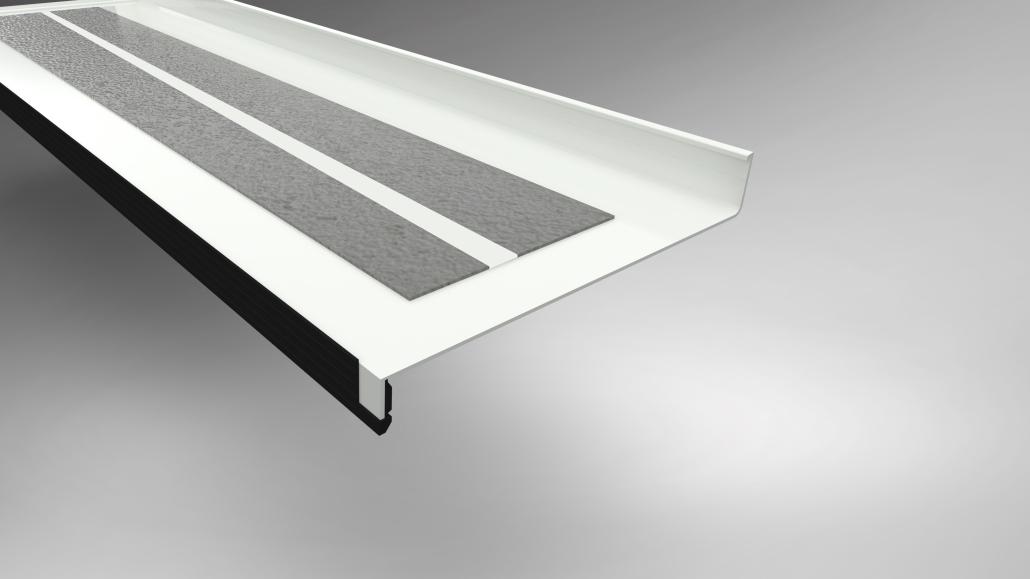

Aluminium window sills are fitted with 1/8’’-1/4’’oval holes arranged at distances of 12’’ between the holes;

– The paint is applied entirely on one side and on the other of the window sills;

– Inclination angle of the windows sills 5°.

– For the correct installation it’s recommended to use the following mounting accessories:

self tapping stainless steel screw

screw cap washer hinged

butyl sealing tape

soundproof tape

low expansion foam

comes in lengths of 120’’ or240’’

available withs

2’’,2.5’’,3.5’’4.5’’,5’’,6’’,6.5’’, 7’’.

RAL 9016/White, RAL 8003/Golden oak, RAL 8019/Brown, RAL 7016/Anthracite Grey

– E6/EV1/Silver, E6/C32/Light bronze, E6/C33/Dark bronze

*in addition custom coatings are available for delivery on request

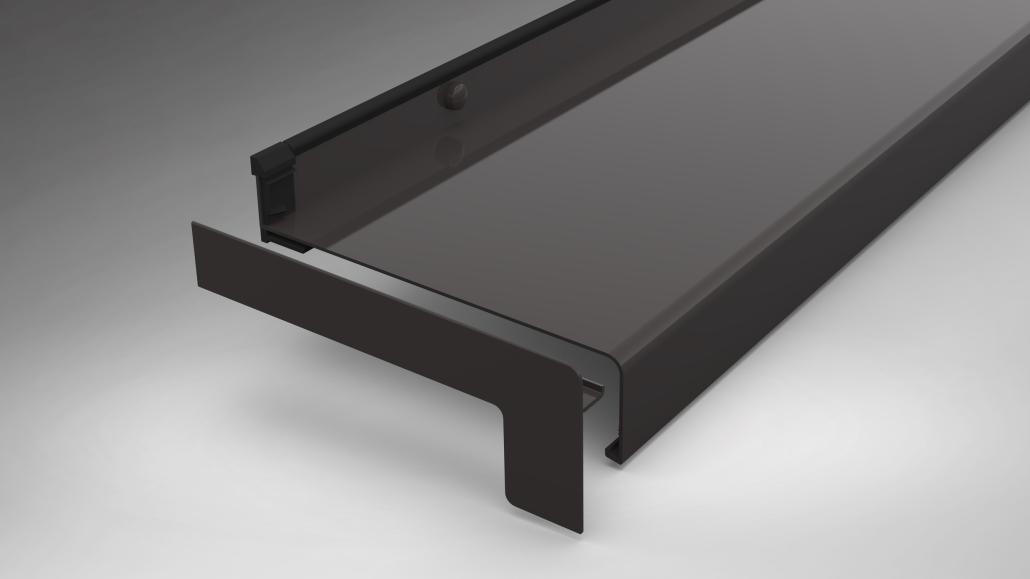

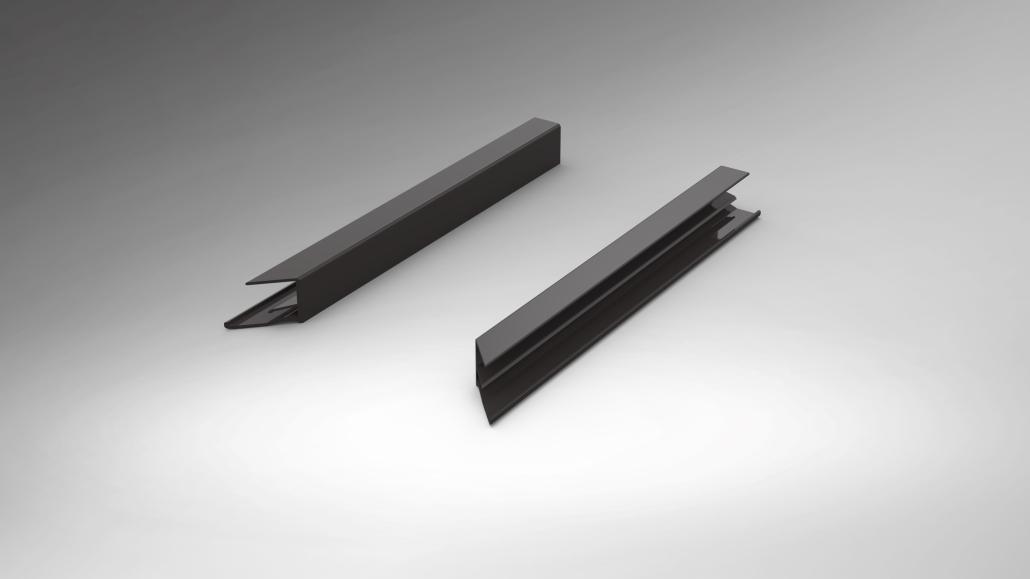

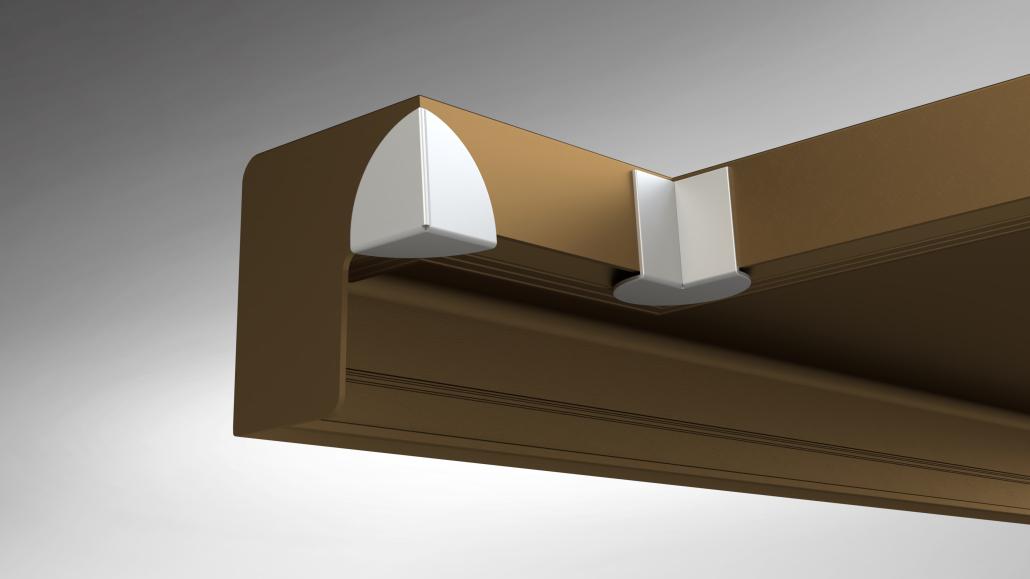

Aluminum end caps

They are made in perfect harmony with the window sills, respecting the quality guarantee and the rigidity adequate to the structure. It installs very easily thanks to our innovative clips-on system.

– The system is recommended to be used for all situations in which the application of thermal insulation represents a later process for realizing the finished facade;

– Outstanding performance and increased strength in terms of maintenance and safety.

available withs

2’’,2.5’’,3.5’’4.5’’,5’’,6’’,6.5’’, 7’’.

RAL 9016/White, RAL 8003/Golden oak, RAL 8019/Brown, RAL 7016/Anthracite Grey

– E6/EV1/Silver, E6/C32/Light bronze, E6/C33/Dark bronze

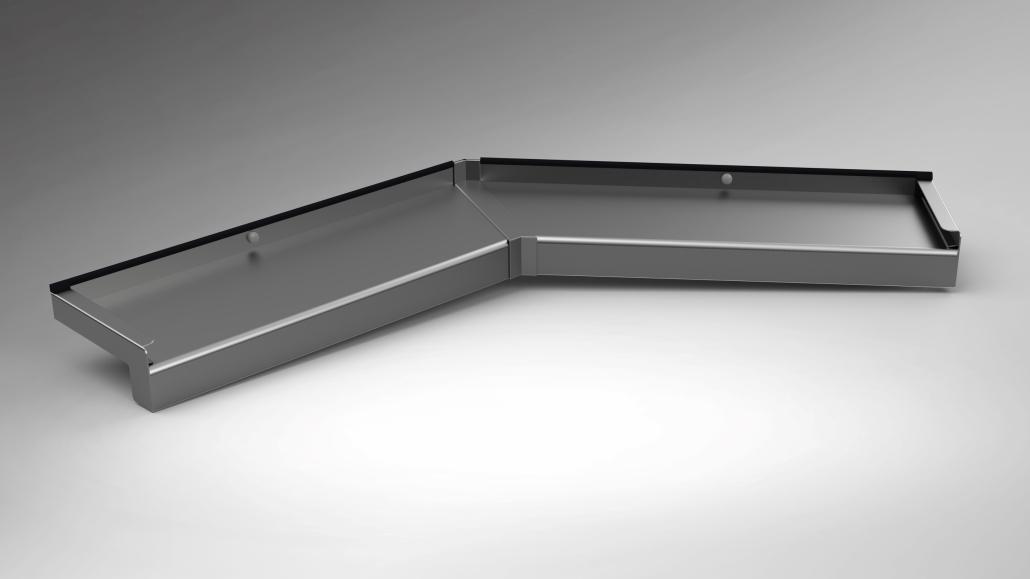

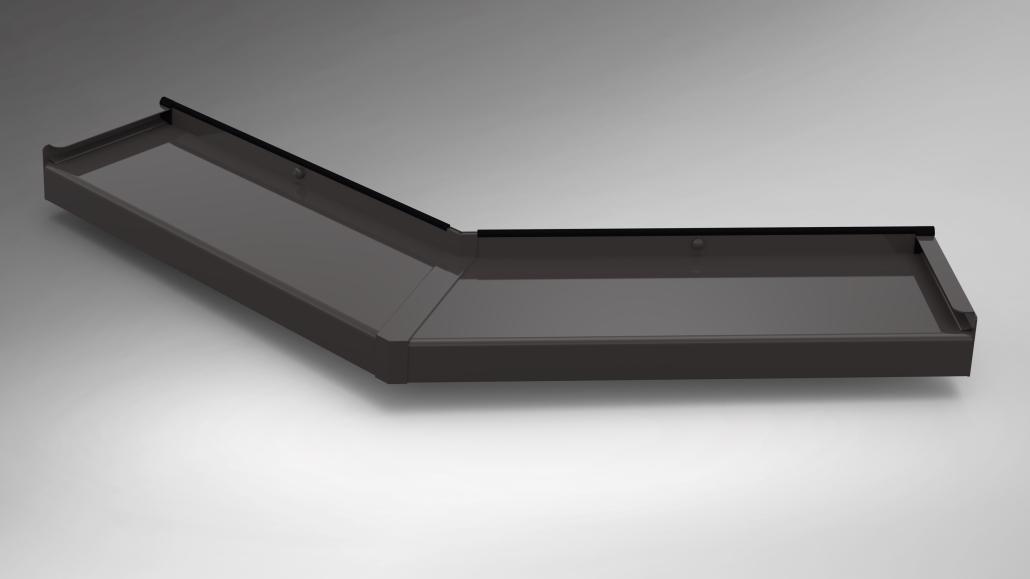

Aluminum Corner Connectors

Corner connectors are designed to be mounted at an angle of 5°, similar to the inclination of the window sill.

– The upper part with a width of 30 mm, allows the masking of angular deviations resulting from cutting the aluminium window sill.

– When using the corner connectors, we recommend installing the window sill accordingly to the mounting instructions described on the product catalogue.

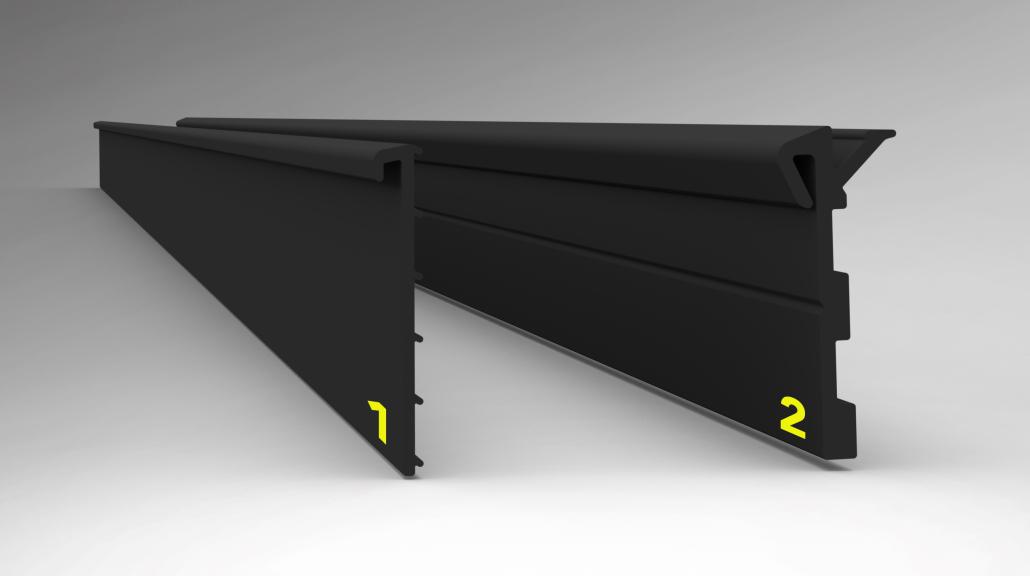

Aluminum Bypass Profile

The bypass profile has a clips-on technology, that is similar with the aluminium end caps clips-on systen, which used together with the butyl tape applied on the joints, results in a durable and resistant system against water penetration.

– The adaptation of bypass profiles is done depending on the guidelines of the construction, taking into account the type end covers used – type “C” / “L”.

Mounting accessories

– low corrosion;

– much firmer tightening than conventional screws;

– prolonged wear resistance – 50 years life;

– low thermal conductivity compared to galvanized screws;

– resistance to shear and traction forces;

– flexibility, resistant to high and low temperatures.

Packing unit: 100 pieces / set

– low corrosion;

– much firmer tightening than conventional screws;

– prolonged wear resistance – 50 years life;

– low thermal conductivity compared to galvanized screws;

– resistance to shear and traction forces;

– flexibility, resistant to high and low temperatures.

Packing unit: 100 pieces / set

Masking caps

– specially designed to cover TX20 self-tapping mounting screws – 3.9×25 mm;

– durability – made of ABS;

– easy to apply;

– wide range of colors: RAL7016, RAL8003, RAL8019, RAL9016, SILVER, BRONZE;

– the washer is attached to the body of the masking cap.

Packing unit: 100 pieces / set

Sealing gaskets

made of EPDM material with a width of 27mm;

– location of use – outside;

– color RAL9005;

– flexibility;

– thermal and chemical resistance;

– easy application on length.

Availability per linear foot , for mounting with or without aluminum sill profile.

Butyl sealing tape

made of butyl rubber, and on the outside aluminium foil;

– resistant to UV radiation;

– application temperatures + 5° C – + 40° C;

– thermal resistance -40° C – + 90° C;

– fast adhesion on most materials;

– classification as waterproofing material;

– self-adhesive;

– insulates against water vapor;

– easy application.

Soundproof tape

made of bituminous membrane;

– location of use – to be mounted outside;

– self-adhesive;

– durability and endurance over time.